Page 1 of 1

75 Westy Type 4 Cooling question

Posted: Sun Dec 06, 2009 10:36 am

by hercdriver

I was tinkering with the 75 Westy yesterday and noticed a lot of air flow around the engine (engine had been at idle for about 5 minutes). I felt around for the source and found most of the air to be flowing out of the engine tin (number 2 spark plug).

I'm assuming this is normal with the lack of spark plug seals. I'm also assuming that the other plug holes aren't producing the same air flow since most of the air is escaping from the first hole it's coming to.

Two questions...

1. Is this the part I need to seal up the plug holes?

https://www.busdepot.com/details.jsp?pa ... 111905449A

2. Is the cooling system operating as designed, or should I be seeing more air from the number 4 hole as well?

Re: Cooling question

Posted: Sun Dec 06, 2009 10:43 am

by Sluggo

1. This place is better, faster & cheaper for parts. Plus shipping is free on orders over $50.

http://www.autohausaz.com/search/produc ... 111905449A

2. Make sure the cooling flap for the left (3/4) side of the engine is opening & closing properly. I had one pop off the inner hinge once.

Posted: Sun Dec 06, 2009 2:34 pm

by Gypsie

After you have confirmed that all the flaps are doin' what they should, if there is still a concern of imbalance, make sure you have flow coming down through the fins.

'Stuff' could be preventing the air from passing the cooling fins.

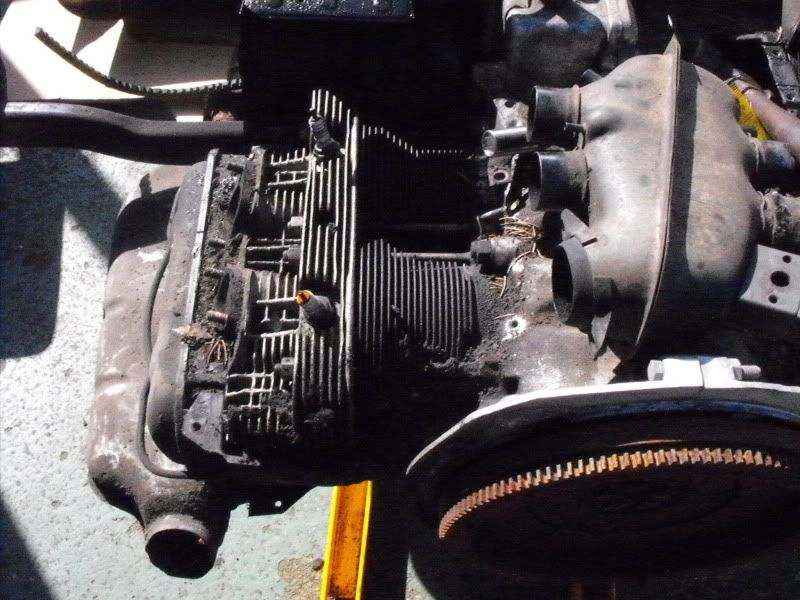

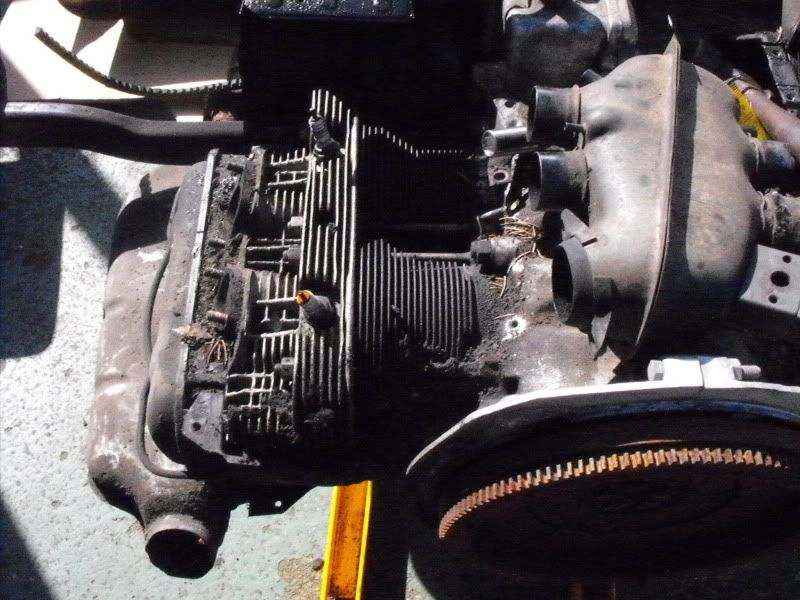

This one was running until it wasn't anymore...

Not much cooling going on here:

Re: Cooling question

Posted: Sun Dec 06, 2009 4:55 pm

by hercdriver

Sluggo wrote:

2. Make sure the cooling flap for the left (3/4) side of the engine is opening & closing properly. I had one pop off the inner hinge once.

Outside of dropping the engine, is there a method making sure both cooling flaps are fully opened?

Re: Cooling question

Posted: Sun Dec 06, 2009 5:10 pm

by hercdriver

$10 shipping killed the deal for me.

Bus Depot wanted $10 for a much larger order. Plus I value the fact that these guys are focused on the bus crowd.

At any rate, the seals have been ordered.

Re: Cooling question

Posted: Sun Dec 06, 2009 7:55 pm

by Amskeptic

hercdriver wrote:Outside of dropping the engine, is there a method making sure both cooling flaps are fully opened?

Yes.

Remove cable to free up shaft, or make sure that the thermostat is fully warm and open.

Right Side: press flap lever forward and then rearward. You should hear a little thunk or clank just behind the #2 sparkplug location.

Left Side: if any doubt about correct assembly, pull #4 spark plug connector out. Get your little telescopic round mirror and a flashlight, and sight back towards the fan housing. You MUST see the vane *drop* down on the oil cooler support pieces with a clank. If you see oil cooler fins and the lever is back all the way, you do not have this important piece.

You can adjust the relative open positions with two pair of vise grips clamped on the cross shaft. First, ensure that the lever is indeed is afar back as it will go. Sometimes you have to loosen the cable a tad. If you need the left side down more securely , use one vise grip to hold the lever stationary while you torsionally bend the cross shaft back towards you on the left side. If the left side is down on the oil cooler support pieces, but the right side is not up as far as it should be, hold the cross shaft near the left with the one pair of vise grips, and rotate the shaft back as far as the lever/right flap stop will let you. OEM fresh right side flaps have little rubber bumpers.

Reference:

Posted: Mon Dec 07, 2009 4:37 am

by Randy in Maine

Might want to look into these FJ40 tie rod boots for the plug wire seals. Much stiffer and stay where they are supposed to. The 5th one is what I use for the oil pressure sender hole.

http://coolfj40.stores.yahoo.net/tierodbootfj.html

Posted: Mon Dec 07, 2009 9:39 am

by Sluggo

Randy in Maine wrote:Might want to look into these FJ40 tie rod boots for the plug wire seals. Much stiffer and stay where they are supposed to. The 5th one is what I use for the oil pressure sender hole.

http://coolfj40.stores.yahoo.net/tierodbootfj.html

That's what I use. The lip holds it right in.

Posted: Tue Dec 08, 2009 6:28 am

by midatlanticys

Nice one Randy - gr8 tip - thank you!! =D>

Posted: Tue Dec 08, 2009 3:15 pm

by Amskeptic

midatlanticys wrote:

Nice one Randy - gr8 tip - thank you!! =D>

Randy, please stick that in the Parts Known To Be Good sticky.

Stick . . . sticky . . . get it? haha, anyways

Posted: Tue Dec 08, 2009 5:28 pm

by Randy in Maine

midatlanticys wrote:

Nice one Randy - gr8 tip - thank you!! =D>

If you decide to get those, PM me and we will have them sent to me and I will send them to you in Portugal.