Page 2 of 3

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Thu Sep 09, 2010 2:24 pm

by 56ovalbug

Amskeptic wrote:

Pretty.... but so much more complicated than the simple '72-'74 exhaust setup.

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Thu Sep 09, 2010 3:39 pm

by sped372

56ovalbug wrote:the simple '72-'74 exhaust setup.

Nice, but so much more complicated than the '68-'71 setup.

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Thu Sep 09, 2010 4:09 pm

by Sylvester

sped372 wrote:56ovalbug wrote:the simple '72-'74 exhaust setup.

Nice, but so much more complicated than the '68-'71 setup.

Yeah baby!

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Thu Sep 09, 2010 7:16 pm

by Amskeptic

Sylvester wrote:sped372 wrote:56ovalbug wrote:the simple '72-'74 exhaust setup.

Nice, but so much more complicated than the '68-'71 setup.

Yeah baby!

[img]ma[/img]

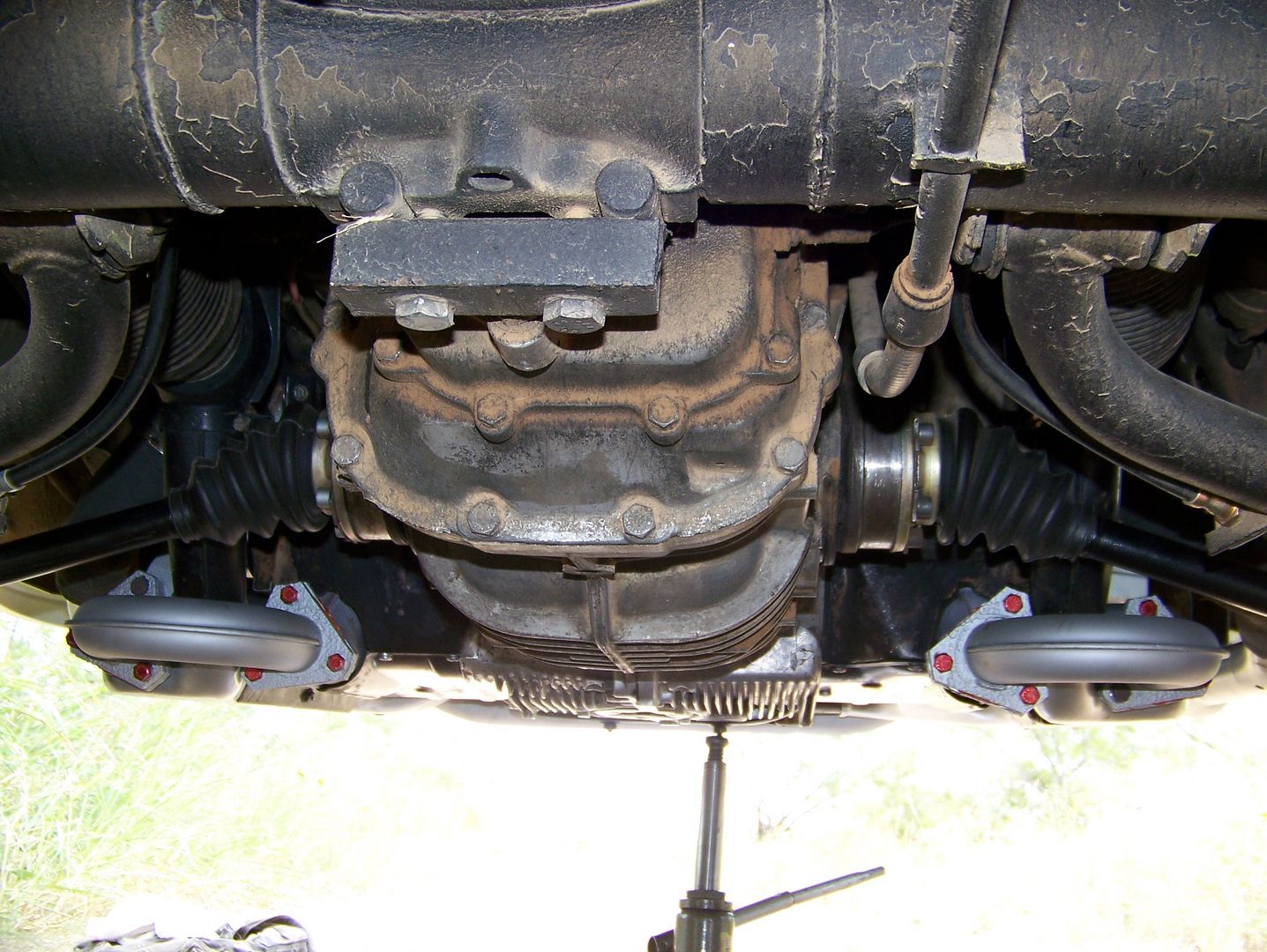

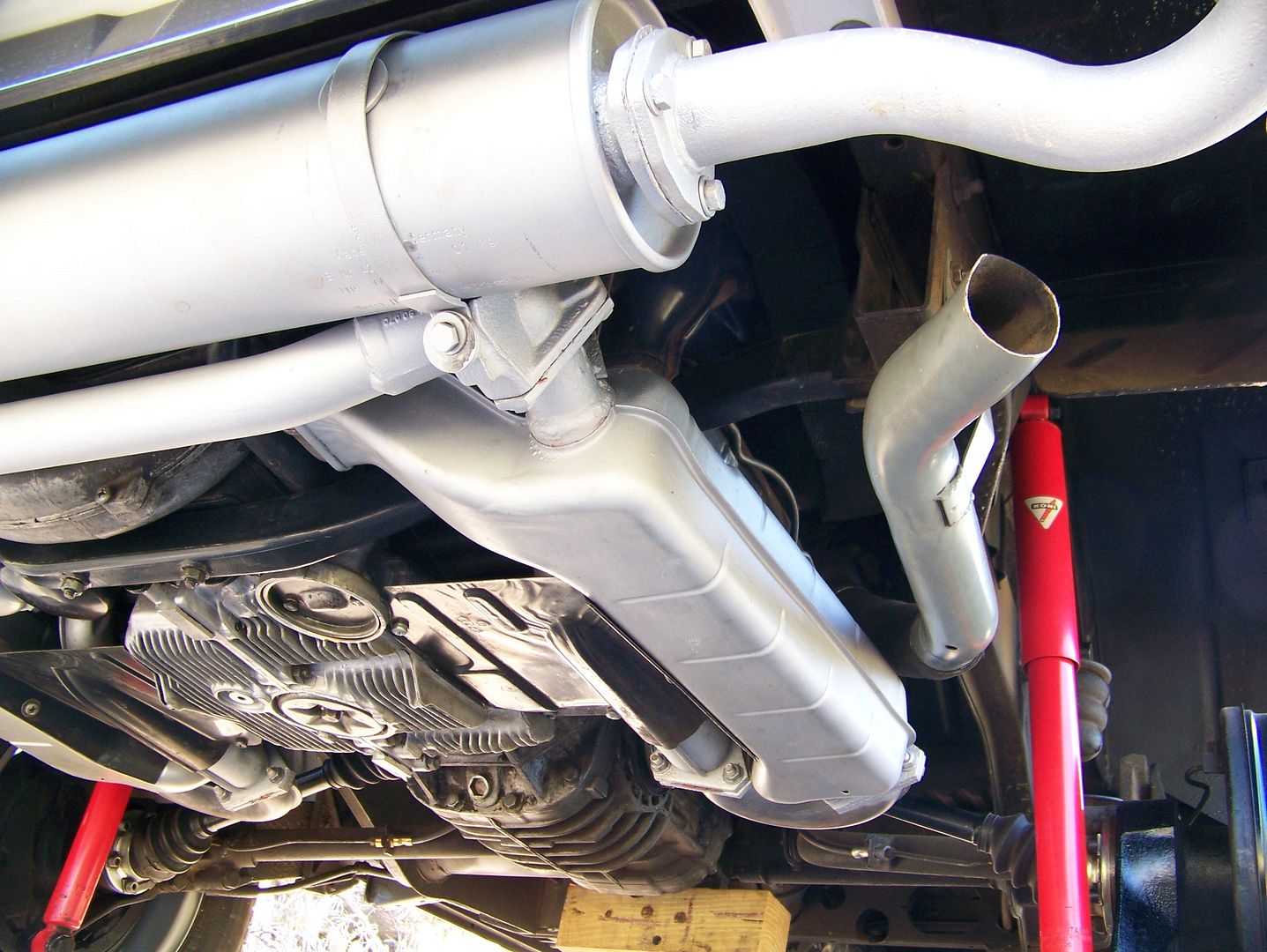

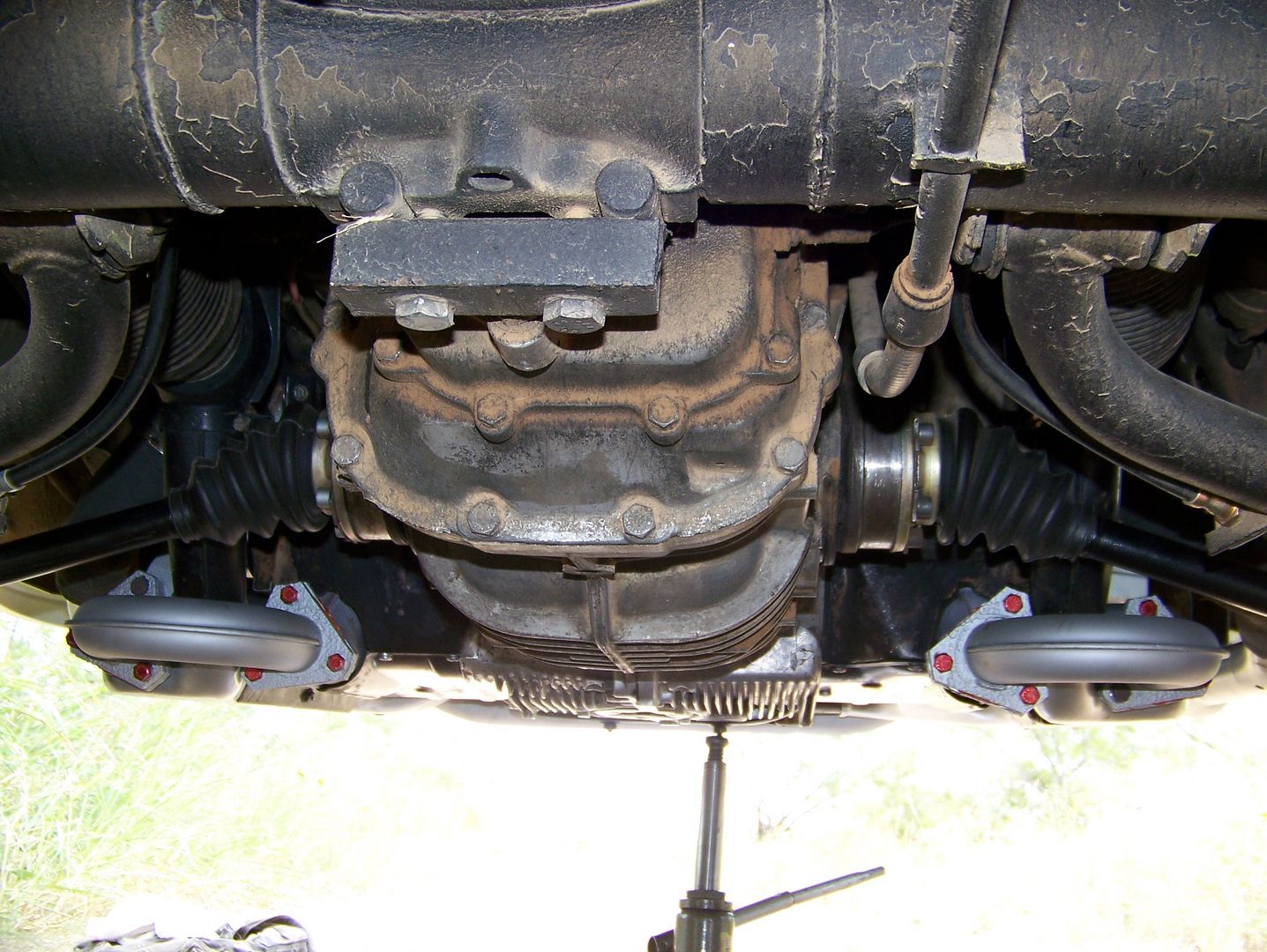

NO! Not quite! The '72-'74 is THE elegant exhaust system of all time.

Three components!

You Type 1 people are always whining and with good reason about those rear "exchangers" not fitting with the collars for the fresh air hoses, and the donut gaskets deteriorating and pinching under the mustache bar and the heat riser flanges not lining up, and the damper pipe bracket not fitting on the perimeter of the damper pipe not to the mention the muffler, oh, on and on.

Colin

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Fri Sep 10, 2010 5:04 am

by Hippie

Amskeptic wrote: Any luck with jacket experiments, Dick? I am thinking why not get outer aluminum flex pipes that are so huge they actually do fit over the flanges, then crush them down with ViseGrips so as to have a "seam" where the ViseGrips mash 'em. Then, what to do with rattling looseness?

ColinTooTiredToThink

What are we making here? Outer skins for heat exchanger cores?

I love to invent and fabricate, so I'm intrigued.

Would fiberglass/resin take the heat?

Re: IAC Greetings From Texas Hill Country (upd 0908)

Posted: Fri Sep 10, 2010 9:14 am

by Amskeptic

Hippie wrote: What are we making here?

Simple jackets for those stupid u-tubes.

Triangular flanges are welded to serious high carbon steel that changes the direction of the exhaust 180* in a matter of inches. The original jackets managed to drop the radiating temperatures a good 100*.

The original jackets were bead welded to the flanges with an all important air gap between the jacket and the pipe underneath.

Colin

Posted: Fri Sep 10, 2010 12:32 pm

by Hippie

Hmmmm...I think something could be done without too much trouble.

Pictures would be nice.

Posted: Fri Sep 10, 2010 6:53 pm

by Amskeptic

Hippie wrote:

Pictures would be nice.

Think: jacket around the those curvy pipes. Have a 1/4"- 3/8" gap between the extant pipes and the jacket-to-be. The original manifolds on this car still have the jackets on them. Very tidy looking. I think they may have fiberglass in between the jackets and the pipes.

Colin

Posted: Sat Sep 11, 2010 8:17 am

by Hippie

I'm thinking a curved "box" with a square cross section would be easiest to make.

Posted: Sat Sep 11, 2010 8:33 am

by dtrumbo

I'm intrigued. I would think square would be harder to make the curve. What type of material are you thinking?

Posted: Sat Sep 11, 2010 10:55 am

by Elwood

Diet Coke Cans would be my guess.

Barb thinkin green

Posted: Sat Sep 11, 2010 3:55 pm

by Hippie

dtrumbo wrote:I'm intrigued. I would think square would be harder to make the curve. What type of material are you thinking?

Prolly galvanized or else 18 gauge mild steel. I'll se if I can come up with a sketch. Do they need to be bolt-on removable or weld on?

I think a outside curve and and inside curve would be easy to bend out of flat stock. Then a U shaped top and bottom.

It's pretty hard to bend tubing that sharp.

Elwood wrote:Diet Coke Cans would be my guess.

Barb thinkin green

Not me. Sugar Coke only for me!

Posted: Sat Sep 11, 2010 4:15 pm

by dtrumbo

I totally get it now. You're right, it's a lot easier to bend flat sheet metal than it is tubing or hose or even a Diet Coke can.

As far as their being able to be removed... I think it would be easier if they could be bolted on rather than welded (I just got a welder for my birthday, but I have no idea how to use it yet). I don't think there's any need to take them on and off, unless you're Colin and you need to paint and wax your U-tubes out in the middle of nowhere while the cops watch.

I'm still thinking using one or more of the three triangle-flange bolts as part of the mounting system might be a way to go.

Thanks for jumping in on this. I was going nowhere fast trying to find hose with an appropriate temp. rating that had a tight enough bend radius.

Posted: Sat Sep 11, 2010 5:11 pm

by Hippie

Sure.

This is rough...it needs spacers and some sort of end covers. Rather than the welds at both top and bottom, the bottom could be flanged over and attached with sheet metal screws.

Posted: Sun Sep 12, 2010 10:30 am

by Amskeptic

Hippie wrote:Sure.

This is rough...it needs spacers and some sort of end covers. Rather than the welds at both top and bottom, the bottom could be flanged over and attached with sheet metal screws.

Interesting. Think of serious heat and vibration here and add water splash that hyper-cools the jacket for an instant. The pipes have been up in the 500-700* range in my limited experience.

Colin