Page 1 of 1

Selector Shaft Positions Prior to Nosecone Refitting

Posted: Fri Jan 22, 2016 10:38 pm

by whc03grady

The selector shafts--which gear should they be in before I remount the nosecone? How do I make sure they're in that gear? Much detail appreciated.

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Jan 23, 2016 1:09 am

by asiab3

The detents have pins that prevent multiple gears from being engaged at the same time. I used neutral as my "staging gear" with good success. I had a longer reply typed up, but it was so riddled with typos on this cellphone, I went for the Guy Fawkes approach of 'blow it up and start again.'

Neutral makes it easy to rotate the hockey stick to check for free movement during assembly. Do you have the trans out and upright? Or is it laying down as if it was installed? (Vertical seems to be the cleanest way to get your sealant concise yet thoroughly applied.)

Robbie

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Jan 23, 2016 2:27 am

by whc03grady

It'll be vertical when I reassemble and seal it. The intermediate shift lever shaft on the 002 5-rib transaxle isn't held in by clips, but rather is trapped in place by the body of the nosecone so vertical assembly seems a must.

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Jan 23, 2016 7:22 am

by Amskeptic

whc03grady wrote:It'll be vertical when I reassemble and seal it. The intermediate shift lever shaft on the 002 5-rib transaxle isn't held in by clips, but rather is trapped in place by the body of the nosecone so vertical assembly seems a must.

That shaft has no groove anywhere?

Colin

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Jan 23, 2016 9:31 am

by whc03grady

Amskeptic wrote:whc03grady wrote:It'll be vertical when I reassemble and seal it. The intermediate shift lever shaft on the 002 5-rib transaxle isn't held in by clips, but rather is trapped in place by the body of the nosecone so vertical assembly seems a must.

That shaft has no groove anywhere?

Colin

kreemoweet wrote:asiab3 wrote: I had E-clips . . .

That would be from the later ( 091 trans ?) modified unit with the springs. I have two working 002 boxes with no e-clips on the shaft, and two spare nosecones

from 002's that clearly show where the pin was sitting on the bottom of the nosecone. And no, they do not stay put without the nosecone in place.

Bad design? You decide!

No groove anywhere. No springs either.

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Jan 23, 2016 2:01 pm

by asiab3

The later assemblies had e-clips like mine, but I thought even the early shafts had a chamfer, decent, or groove on one end to "locate" the shaft in the bracket. If not, well, with a vertical assembly you have gravity as an assisting "third hand." You should be able to engage the hockey stick into its bushing, then slide he nosecone down over it while the whole assembly stays still. It's awkward to type about, but easy to accomplish physically.

Try its few times without sealant to get a feel for it. No mess, no harm!

Robbie

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Feb 27, 2016 2:54 pm

by whc03grady

asiab3 wrote:Neutral makes it easy to rotate the hockey stick to check for free movement during assembly.

whc03grady wrote:Much detail appreciated.

I.e., how do I put it in neutral?

What can be screwed up here, frankly?

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Feb 27, 2016 3:32 pm

by asiab3

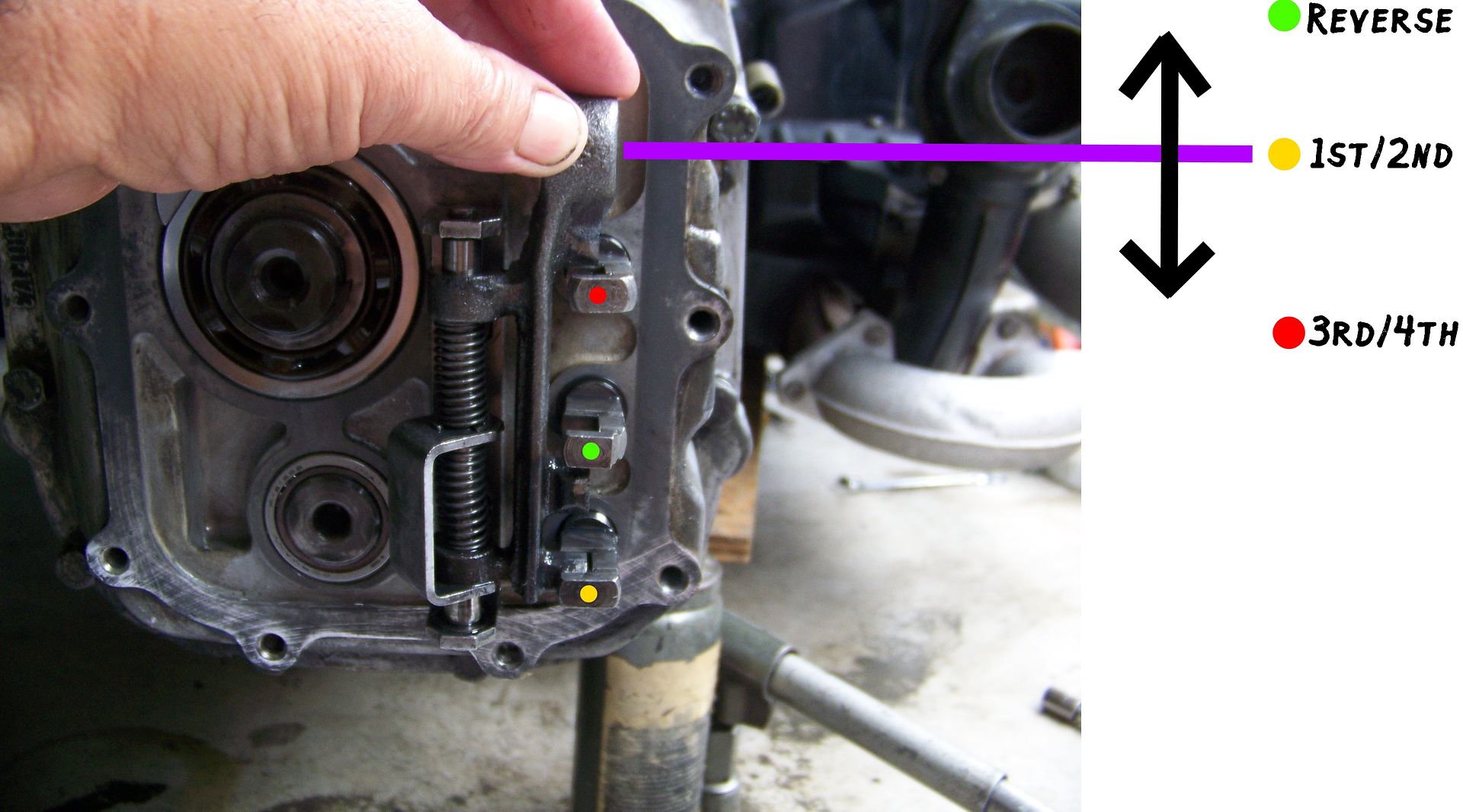

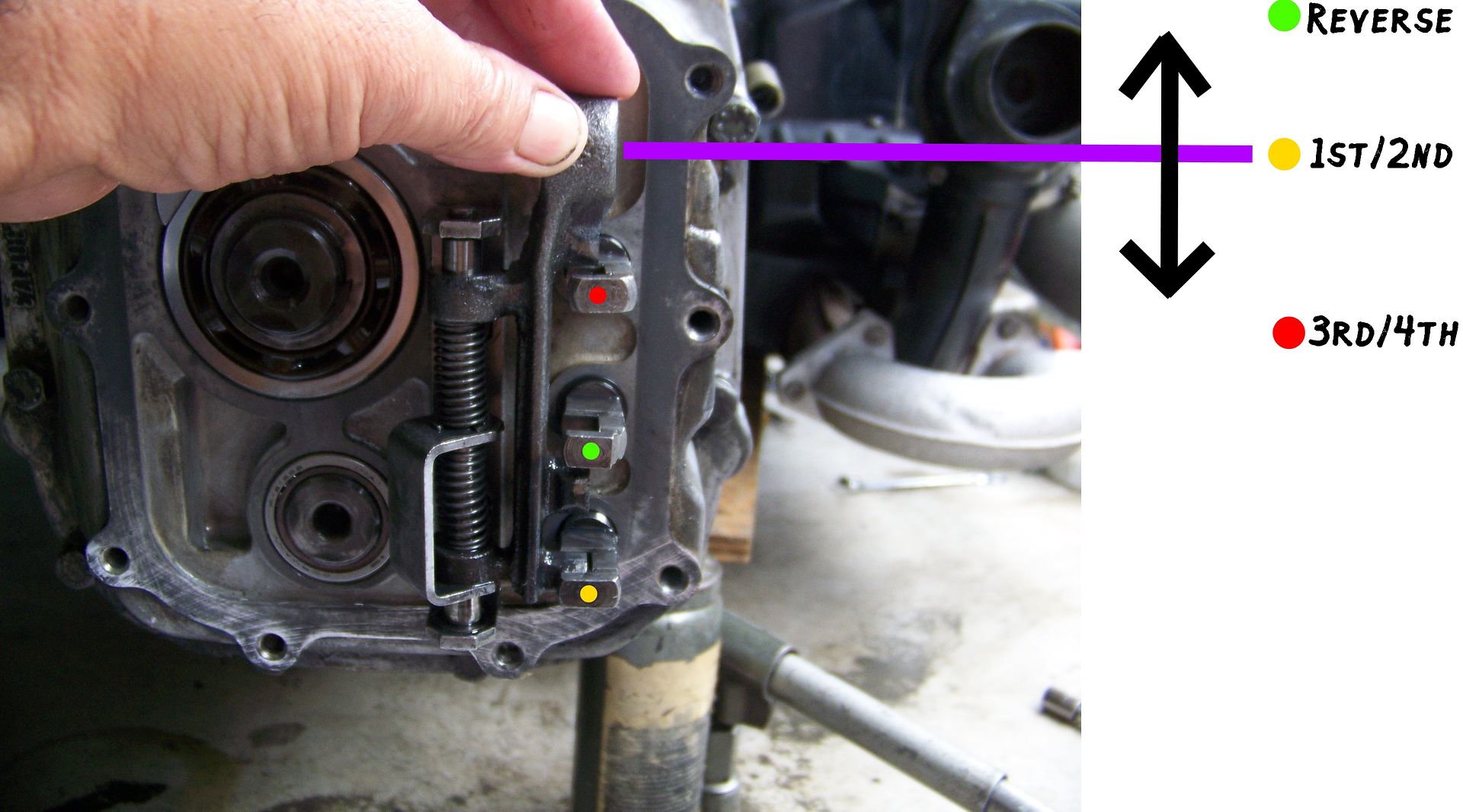

You have the nosecone off, correct? The three gear selector shafts (shows below with a red, green, and yellow dots,) must be "level" with each other when viewed from the side. If one is pushed in or pulled out, a gear will be selected. (Also, if one is pushed in or pulled out, you will not be able to select any other gears.)

Here they are, lined up, blurry, and in neutral:

See how the gear selector (the vertical "shuttle" that interfaces with the bushing and the selector shafts) has pawls that interact with each selector shaft but never more than one at a time? The gear selector must be free to run up and down the pin/shaft; that confirms you are in neutral. If a selector shaft is sticking out or in, you can muscle up some strength to overcome the 15-25 pounds of force required to "change" gears. (See how the long bus shifter in the cabin helps multiply our leverage to overcome these "detents"?) I wouldn't use pliers or a lever on the shafts; if you need to move one, hand force should be enough. If not, rotate the input shaft a little and keep trying.

Possible screw-ups include grit in the bearings/bushings, the guiding pin/shaft going in upside down and/or falling out before you get the nosecone on, (easier to install nosecone with trans sitting upright on the bell housing,) over-torquing the nosecone bolts if you have them (Rancho has a 50:50 chance of building the transaxle with studs, correctly, or bolts, incorrectly.) Other than that, I can't imagine a scenario where the components will install completely together and not function; they won't allow an incompletely assembly as far as I know.

Robbie

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Mon Feb 29, 2016 1:29 pm

by whc03grady

Thank you, asiab3: that was very helpful.

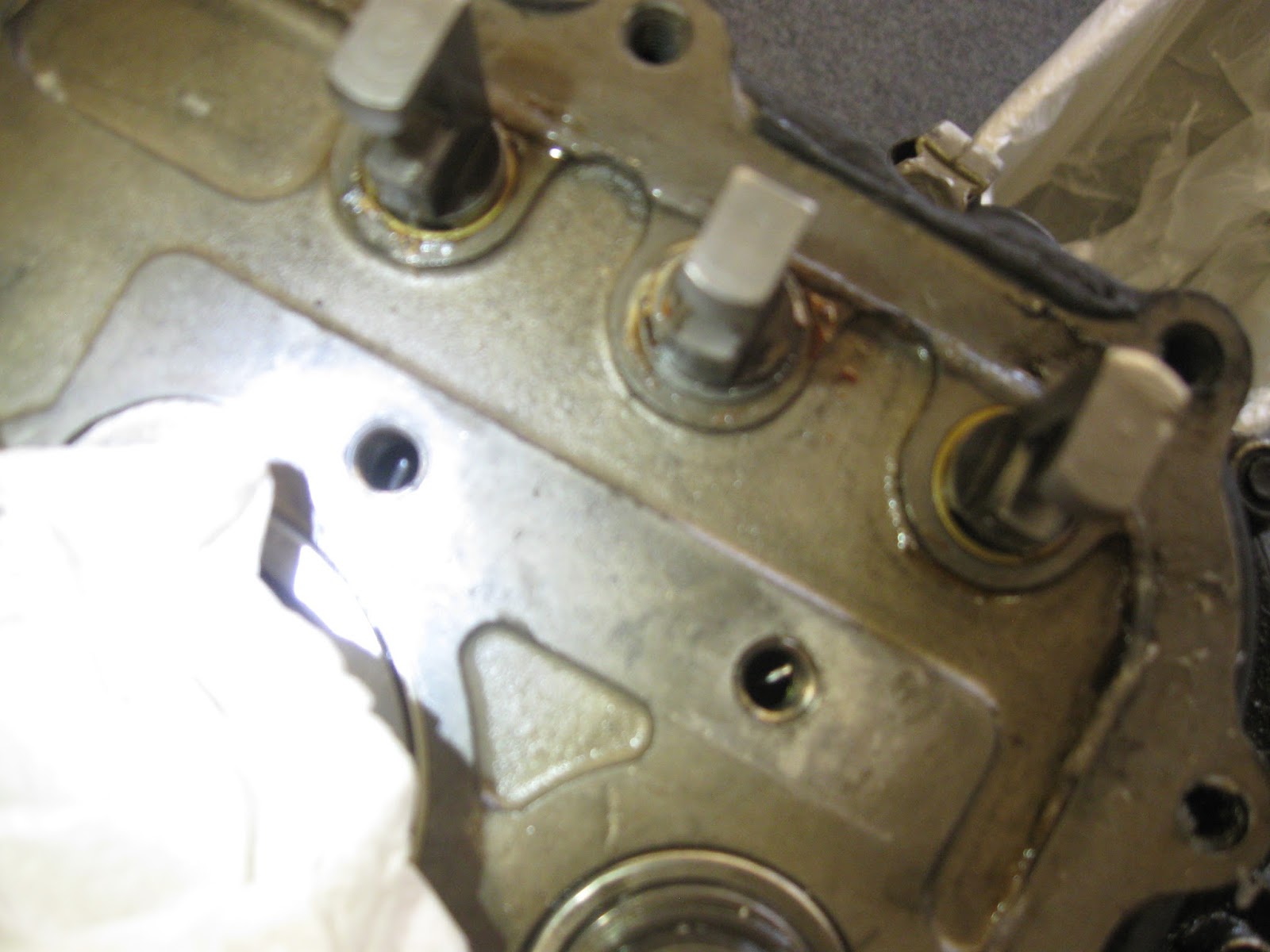

Here's the inserts, replete with timebomb tangs. The bolts are confirmed not to contact them.

My machinist couldn't find inserts matching the OG bolts (the size x thread pitch is weird apparently?), so we went to the closest he had. Stayed metric, of course. Except that I torqued them to 18 ft-lbs.

This is the stuff, right?

Proof that the 002 5-rib, aka pyramid, transaxle's selector shaft just rests on the nosecone housing.

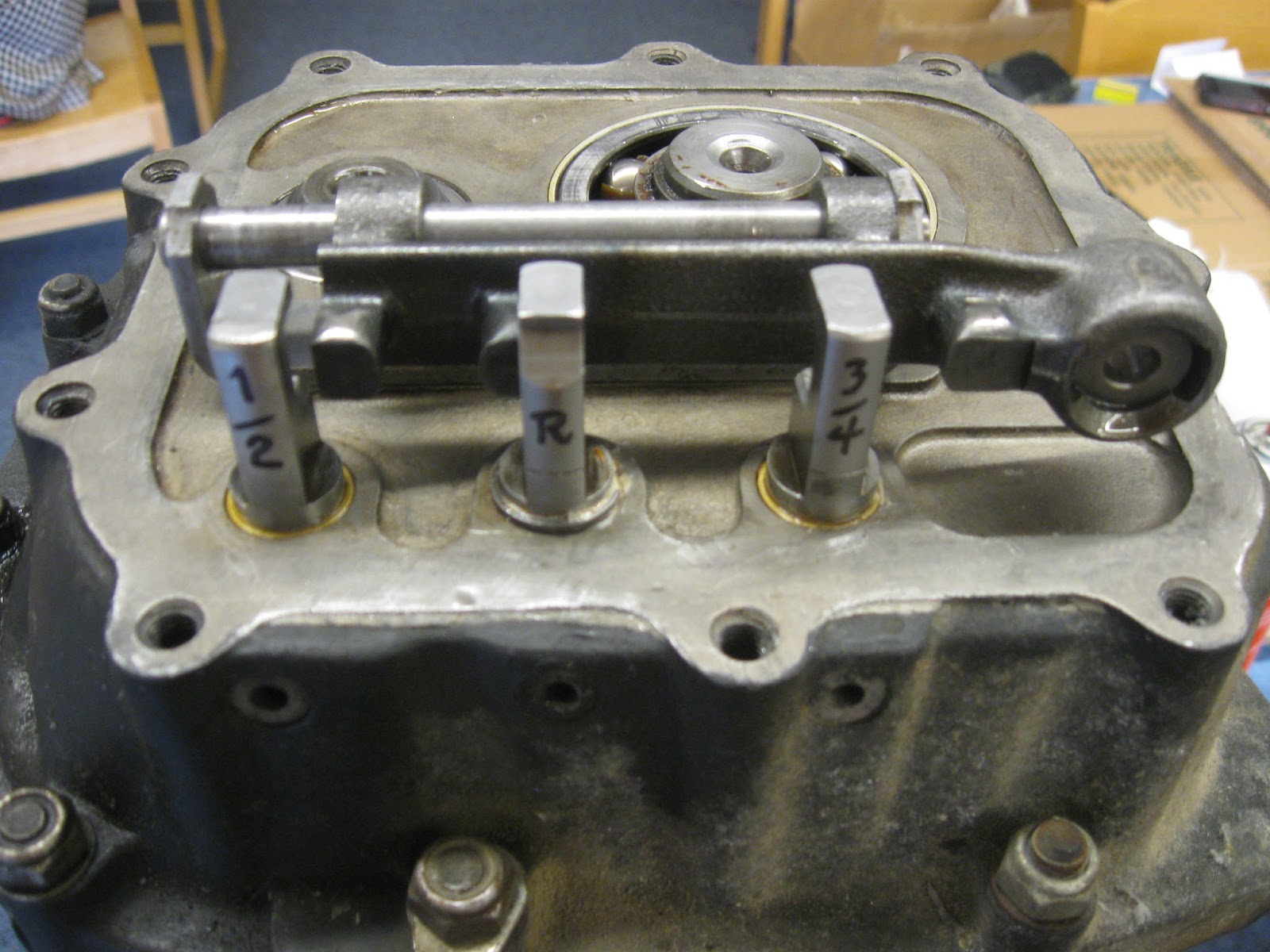

Here's where I am, in neutral, ready for nosecone refitment, once I put the hockey stick on there. And the gasket. Btw, the gasket: it doesn't perfectly line up over that big bearing. Should I glue it to the nosecone, then glue the nosecone to the gear carrier?

Another question, for personal enlightenment: why doesn't the Reverse pawl line up so neatly inside the cutout of the selector shaft, as do the 1/2 and 3/4 pawls? That's ready to select Reverse up there, yet half the pawl sticks out the bottom of the cutout.

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Wed Mar 02, 2016 7:51 pm

by Amskeptic

whc03grady wrote:

Another question, for personal enlightenment: why doesn't the Reverse pawl line up so neatly inside the cutout of the selector shaft, as do the 1/2 and 3/4 pawls? That's ready to select Reverse up there, yet half the pawl sticks out the bottom of the cutout.

Those are not "pawls", they are the selector fork shafts. Reverse shaft has only neutral (as photographed) and a pull into reverse. The other selector shafts are in neutral right now, but also must do push shifts (1st and 3rd). That is why those shafts have additional visible surface sticking up.

Colin

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Tue Mar 08, 2016 12:11 pm

by whc03grady

Amskeptic wrote:Those are not "pawls", they are the selector fork shafts. Reverse shaft has only neutral (as photographed) and a pull into reverse. The other selector shafts are in neutral right now, but also must do push shifts (1st and 3rd). That is why those shafts have additional visible surface sticking up.

Colin

Hey, don't lookit me, I was just using asiab3's terminology up there. My question was actually, why is the reverse shaft (I'd rather call it a 'tab', frankly, but whatevs

) so much wider; notice how the other tabshafts fit quite neatly into the cutouts (more pix

here), yet the reverse shaftab sticks halfway out the bottom.

In other questions, the gasket? Glue it to the nosecone, then glue all that to the gear carrier? Glue it to the gear carrier, then glue on the nosecone? It doesn't line up exactly right with the bearing, though it does with the bolt (not stud) holes. And then, my glue--is that the right Permatex aviation guck?

Re: Selector Shaft Positions Prior to Nosecone Refitting

Posted: Sat Mar 12, 2016 6:08 am

by Amskeptic

whc03grady wrote:Amskeptic wrote:Those are not "pawls", they are the selector fork shafts. Reverse shaft has only neutral (as photographed) and a pull into reverse. The other selector shafts are in neutral right now, but also must do push shifts (1st and 3rd). That is why those shafts have additional visible surface sticking up.

Colin

Hey, don't lookit me, I was just using asiab3's terminology up there. My question was actually, why is the reverse shaft (I'd rather call it a 'tab', frankly, but whatevs

) so much wider; notice how the other tabshafts fit quite neatly into the cutouts (more pix

here), yet the reverse shaftab sticks halfway out the bottom.

In other questions, the gasket? Glue it to the nosecone, then glue all that to the gear carrier? Glue it to the gear carrier, then glue on the nosecone? It doesn't line up exactly right with the bearing, though it does with the bolt (not stud) holes. And then, my glue--is that the right Permatex aviation guck?

Permatex Aviation and however you can get the gasket nicely indexed. Mechanic's Discretion.

) so much wider; notice how the other tabshafts fit quite neatly into the cutouts (more pix here), yet the reverse shaftab sticks halfway out the bottom.