your right, that isn't gear oil.

I removed the 17mm fill plug on the trans and checked, its just a hair below the edge of the hole. doesn't appear any is missing.

also, it smells WAY different from engine oil.

sooooo, its engine oil that is leaking.

the question remains, from where and what to do to stop it?

I am not currently setup with the tools or knowledge to check my endplay unfortunately. ill read up on it and see if I can get that number.

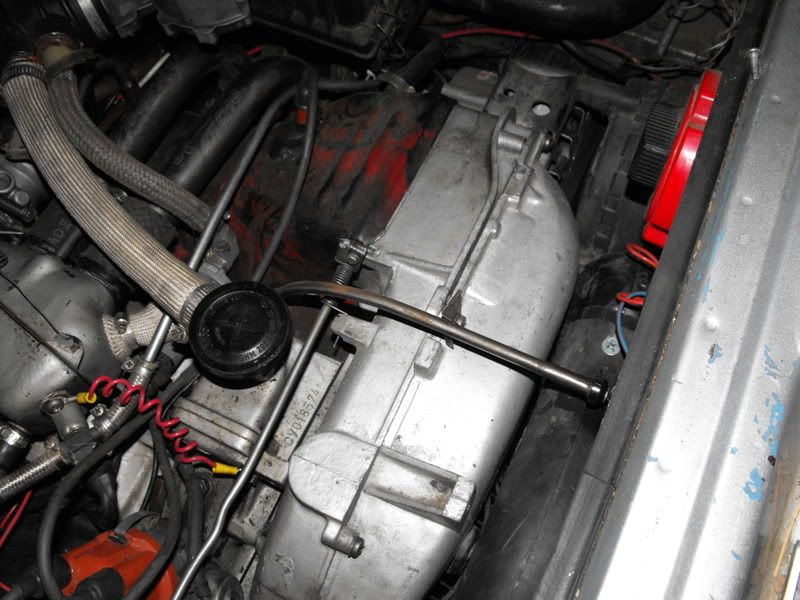

I tried to clean things up a bit to see if it would give a better idea of where the oil is coming from.

these 'galley plugs' if that is what they are called, DO look dirty, but it looks like some kind of sealant that is just gummed up around them. they don't seem to show any specific signs of leaking (that I can tell, having no experience looking for an oil leak prior to now)

the 'cam plug?' also seems to just be covered in that thick black sealant, and not specifically leaking oil that I can tell:

the rear main seal also looks to be in perfect condition. Im not sure what I should be looking for exactly, but I don't see any cracks or tears or signs of it being misshapen or deformed in any ways. as mentioned before there was some of that sealant dripping down over that very top part of it, but that's it.

when you reference 'heat marks' - is this them? those sorta red/blueish colored area's?

the clutch disc seems dry as a bone, the only residue I could find on it is a darkish colored dust:

so, go get the flywheel and clutch disc resurfaced, and then just swap out the main seal, flywheel o-ring (and wherever that felt washer goes) and slap it together and hope for the best?

I don't see what else I can address with what I currently have taken apart.