Re: hydraulic lifters...pushrods...

Posted: Sat Mar 09, 2013 5:00 pm

??? You ask me this question, and then answer it yourself in your next paragraph...I await your reply with one question:

If a cam lobe is pushing a lifter open on one side of the engine, then goes over to the other side to open another lifter, how is that not "twice as much" as a typical engine?

Why? Are you testing me, or just want it printed online to educate the masses? I have no problem with either.

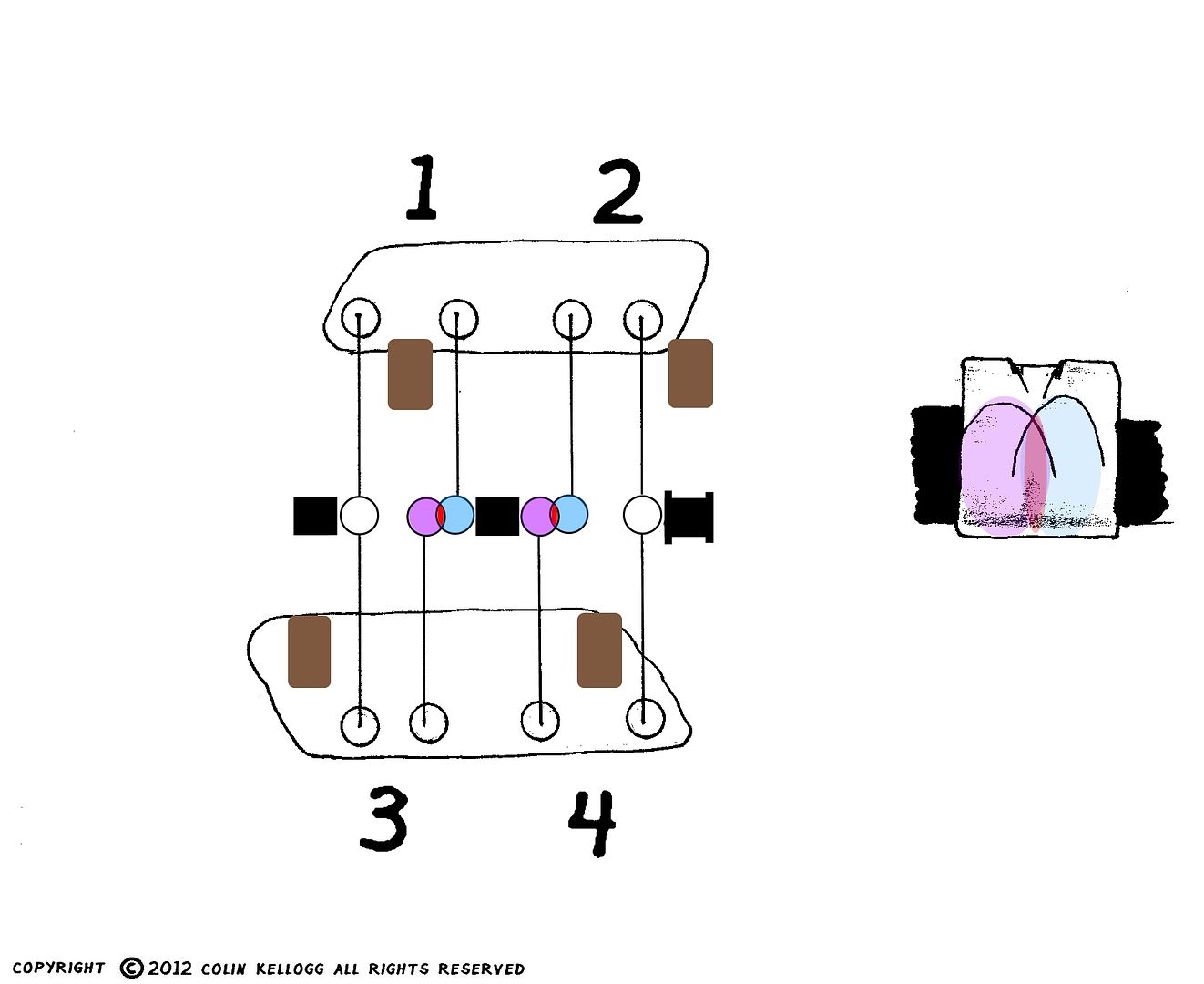

Oh well, here goes... Let's use the #1 and #3 intake as examples. easy to pull, easy to view. Lobe#2 on the cam.

- On the #3 side, the lifter runs so far forward on the lobe, it actually hangs off the edge. On the #1 side, the lifter runs so far back, it hangs off of the back of the same lobe. The lobes on those type 4's are as long or longer than the cam bearings!

- Although 2 lifters run on the same lobe, the contact points are very much separated.

- Although 2 lifters run on the same lobe, the lifters contact different, separate, parts of the cam.

- Although 2 lifters run on the same lobe, the work and wear that is done is in 2 VERY separate places.

If we look at type 1's, I agree 7053%. Short lobes, both lifters contacting same spot, 2 wipes on same contact spot of lobe per revolution of cam, twice the work and wear in the same spot. Yes sir...

But we are not. We are talking type 4. LONG lobes, both lifters contacting DIFFERENT SPOTS, 2 wipes on DIFFERENT CONTACT SPOTS of lobe per revolution of cam, twice the work, BUT 2 different spots, which equals 2 single instances of work in 2 separate places...

Let me be clear. I FULLY understand what you are saying. However, my discussion on this thread is "work" and "wear" per lifter, per contact point, which equals ONE.

Your last comment, "Are you familiar with it?".

You are kidding, right??? My friend, I still have dreams about those Nazi drill sergeant teachers swinging around a cam without a gear like a ruler they were gonna rap on my knuckles to drive home a point...

Most respect and good to you, Walt.