Another Engine Build thread stock type 1 dp (Happy Ending)

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Agonizingly closer but not yet.

Pulled the D bolts off the failed transmission. Never had issues with the starter D bolt on the bus. The engine pulled was a single port with no doghouse cooler. Much easier to get to the nut on a D bolt without the doghouse in the way. Pesky details. I thought I did good spotting the missing lower stud on the engine case this morning.

Sigh.

Tomorrow,

neal

Pulled the D bolts off the failed transmission. Never had issues with the starter D bolt on the bus. The engine pulled was a single port with no doghouse cooler. Much easier to get to the nut on a D bolt without the doghouse in the way. Pesky details. I thought I did good spotting the missing lower stud on the engine case this morning.

Sigh.

Tomorrow,

neal

The slipper has no teeth.

- hambone

- Post-Industrial Non-Secular Mennonite

- Location: Portland, Ore.

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Go, boy!

http://greencascadia.blogspot.com

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

The D bolt on the driver's side isn't going to thread through from the engine side. I thought that if it could I might get a set of vice grips onto the head and bolt it that way.

Yes, the case that came out of Bertha, the dead case on it's last align bore, sure enough has threads in that corner so you just thread the bolt in from under the car to tighten. I think I can pull the threaded assembly and press it into the new engine case after routing out the current hole a couple of millimeters.

Soooo, engine comes out. Annoying. The universe has decided I need the practice.

neal

Yes, the case that came out of Bertha, the dead case on it's last align bore, sure enough has threads in that corner so you just thread the bolt in from under the car to tighten. I think I can pull the threaded assembly and press it into the new engine case after routing out the current hole a couple of millimeters.

Soooo, engine comes out. Annoying. The universe has decided I need the practice.

neal

The slipper has no teeth.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

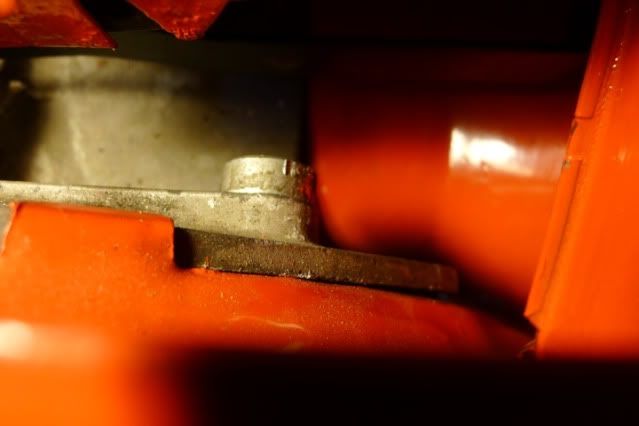

Threaded assembly popped out real nice. Here it is half way out.

Has anyone done this? Splining. If I drill out the hole to a less than tight fit for the end of the barrel without the splining, will the splines press in? Would have to pull it into the other case with a bolt. No room to tap. It should work. If I drill out the hole in the new engine's case to 14 mm, that gives the splines .6 mm to cut in.

And that thing sure is tang red.

neal

Has anyone done this? Splining. If I drill out the hole to a less than tight fit for the end of the barrel without the splining, will the splines press in? Would have to pull it into the other case with a bolt. No room to tap. It should work. If I drill out the hole in the new engine's case to 14 mm, that gives the splines .6 mm to cut in.

And that thing sure is tang red.

neal

The slipper has no teeth.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Success! At least getting the threaded insert into the case. Now back into the car, and making sure the other D bolt stays in place.

neal

neal

The slipper has no teeth.

- hambone

- Post-Industrial Non-Secular Mennonite

- Location: Portland, Ore.

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

You're almost there!!!!!!!!!!!!!!! This is penance for too many years of puttin' this stuff off.

http://greencascadia.blogspot.com

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Engine is in car, securely bolted to the transaxle. Whew.

Sure glad the threaded insert from the newer case went in ok. Kind of committed once the drill bit hit the case.

Of course I didn't have a 14 mm drill bit, so 12.6 had to do with a bit of hand filing after the fact.

I put the old transaxle onto the engine to pull the insert in as the bolt had a flat space to work against, and a bit of length to lessen the odds of it going in crooked. Used a longer bolt to start with as the original might have only gotten a thread or two into the insert and I wanted the bolt onto all of the thread.

It worked!

Of course immediately after beginning drilling it dawned on me that I could have taken the dog house tin off and had as much room as on the other side to get washer and nut onto the D bolt. A pain, but probably would have been doable.

neal

Sure glad the threaded insert from the newer case went in ok. Kind of committed once the drill bit hit the case.

Of course I didn't have a 14 mm drill bit, so 12.6 had to do with a bit of hand filing after the fact.

I put the old transaxle onto the engine to pull the insert in as the bolt had a flat space to work against, and a bit of length to lessen the odds of it going in crooked. Used a longer bolt to start with as the original might have only gotten a thread or two into the insert and I wanted the bolt onto all of the thread.

It worked!

Of course immediately after beginning drilling it dawned on me that I could have taken the dog house tin off and had as much room as on the other side to get washer and nut onto the D bolt. A pain, but probably would have been doable.

neal

The slipper has no teeth.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Penance? Years of putting stuff off? Only months. Dealing with it as the hand is dealt to me. I did have that interruption of getting Ramona's engine and transaxle into Bertha. Putting off more ambitious projects into new areas while striving to keep our runners running. Both mechanical failures led me to the school of critical design changes during the tumultuous transition to a dual port norm.hambone wrote:You're almost there!!!!!!!!!!!!!!! This is penance for too many years of puttin' this stuff off.

neal

The slipper has no teeth.

- hambone

- Post-Industrial Non-Secular Mennonite

- Location: Portland, Ore.

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

I was mainly thinking of that engine on the bench for 12,000 years. And that other stuff you put off because you were broke.

So you start that thing yet? I do like the orange.

So you start that thing yet? I do like the orange.

http://greencascadia.blogspot.com

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Tang Red.

Still getting things hooked up. Took yesterday off. Currently trying to figure out how to get the accelerator tube that goes through the fan shroud through the new engine seal that blocks it. What's up with that?

neal

Still getting things hooked up. Took yesterday off. Currently trying to figure out how to get the accelerator tube that goes through the fan shroud through the new engine seal that blocks it. What's up with that?

neal

The slipper has no teeth.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

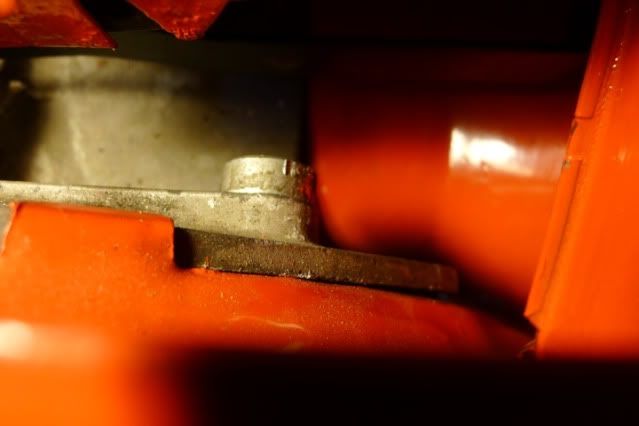

Wouldn't you know it. Another issue.

Got the accelerator cable through the engine seal, and buffed up an oil drain plate, grabbed a gasket set, the screen and new acorn nuts, and the screen wouldn't fully seat. WTF?

The oil pickup assembly is wonky, and the tab that bolts to the bottom of the case is bent over and in the way.

And I noticed one of the little studs was longer than the rest. Concerned the acorn nut wouldn't seat, I threw an acorn nut onto that stud to thread it in a bit further. It did, but then of course the acorn nut wouldn't come off, so I backed the stud completely out. A real long one. All the others were flush with the floor of the case on the inside.

Alas, it never occurred to me that it was long because the oil pickup assembly is bolted down to the inside end. Fished the nut out with a magnet. It's on the stud in the photo above. Any ideas would be appreciated.

F*** me.

neal

Got the accelerator cable through the engine seal, and buffed up an oil drain plate, grabbed a gasket set, the screen and new acorn nuts, and the screen wouldn't fully seat. WTF?

The oil pickup assembly is wonky, and the tab that bolts to the bottom of the case is bent over and in the way.

And I noticed one of the little studs was longer than the rest. Concerned the acorn nut wouldn't seat, I threw an acorn nut onto that stud to thread it in a bit further. It did, but then of course the acorn nut wouldn't come off, so I backed the stud completely out. A real long one. All the others were flush with the floor of the case on the inside.

Alas, it never occurred to me that it was long because the oil pickup assembly is bolted down to the inside end. Fished the nut out with a magnet. It's on the stud in the photo above. Any ideas would be appreciated.

F*** me.

neal

The slipper has no teeth.

- hambone

- Post-Industrial Non-Secular Mennonite

- Location: Portland, Ore.

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

That is a tricky one...it will take some care to not damage the case trying to tap it back into place.

Try it lightly and see if it could work. Otherwise, then what???

The stud is no big deal at least.

How did this happen? Man.

Try it lightly and see if it could work. Otherwise, then what???

The stud is no big deal at least.

How did this happen? Man.

http://greencascadia.blogspot.com

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

http://pdxvolksfolks.blogspot.com

it balances on your head just like a mattress balances on a bottle of wine

your brand new leopard skin pillbox hat

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Some kind of wedge that threads out braced against the case on one side and the bent pickup assembly on the other? With the stud there to keep the hole for the bolt down aligned. Then once the pickup is out of the way that the screen can fully seat, JB Weld the holy bejeeezus out of the tab and stud?

neal

neal

The slipper has no teeth.

-

bajaman72

- Addicted!

- Location: Quartz Hill, CA

- Contact:

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

I recently pulled a seized engine apart with the same problem. Except they figured it was a good idea to just leave the screen out:( I found a coil nut stuck in the oil pump!

It looked like (to me) it was caused by the longer stud being driven too far up and deforming the pickup tube.

It looked like (to me) it was caused by the longer stud being driven too far up and deforming the pickup tube.

1968 Karmann Ghia - Driver

1969 Transporter - Project

1959 Karmann Ghia - Full Race Car

1969 Transporter - Project

1959 Karmann Ghia - Full Race Car

- SlowLane

- IAC Addict!

- Location: Livermore, CA

- Status: Offline

Re: Another Engine Build thread stock type 1 dp

Neal, I think you'll want to be very careful about applying any significant amount of force to the pickup tube assembly. If you jiggle it around much, you'll ruin the fit of the other end of tube where it sockets into the case. Then your oil pump will just be sucking air.ruckman101 wrote:Some kind of wedge that threads out braced against the case on one side and the bent pickup assembly on the other? With the stud there to keep the hole for the bolt down aligned. Then once the pickup is out of the way that the screen can fully seat, JB Weld the holy bejeeezus out of the tab and stud?

What exactly is blocking the strainer from going in? The placement of the tube or the bent tab? Make sure you're fixing the right thing and not making assumptions.

I'm looking at page 41 in the engine chapter of my old Beetle Bentley. Figure 16-3 shows how the oil pickup fits into the case. From the looks of the curvature on the tube in the picture, the curve you see on the visible part of the tube might very well be a continuation of the curve that you can't see on top. What I'm saying is that what you've got there might be normal. Try to peek inside the tub and see if it seems to have a smooth curve or is kinked.

Secondly, is the hole in the mounting tab lined up with the threaded hole in the case? If it is, then I suggest maybe you can bend your strainer a bit to fit around the tab. If it isn't, then try to find some way of keeping the pickup tube assembly immobile wrt. the case as you gently pry the tab so it aligns.

Suggestion for getting the stud and nut back onto the mounting tab: fit the nut into a closed-end wrench and see if you can't sneak it through the small gap between the strainer hood and the case and position it over the threaded hole. Offset wrench might be necesssary. Then thread the stud up through the threaded hole and catch the stud on the nut as it runs up. Tighten nut once enough threads have gone through. I know, not as easy as it sounds. You might need to file/grind out some of the hood (yuck) to get enough clearance.

Good luck.

Lyle

'81 Canadian Westfalia (2.0L, manual), now Californiated

"They say a little knowledge is a dangerous thing, but it is not one half so bad as a lot of ignorance."

- Terry Pratchett

"They say a little knowledge is a dangerous thing, but it is not one half so bad as a lot of ignorance."

- Terry Pratchett