Moderators: Sluggo, Amskeptic

-

LiveonJG

- IAC Jester!

- Location: Standing on the side of the road, rain falling on my shoes.

-

Status:

Offline

Post

by LiveonJG » Sat Mar 14, 2009 3:33 pm

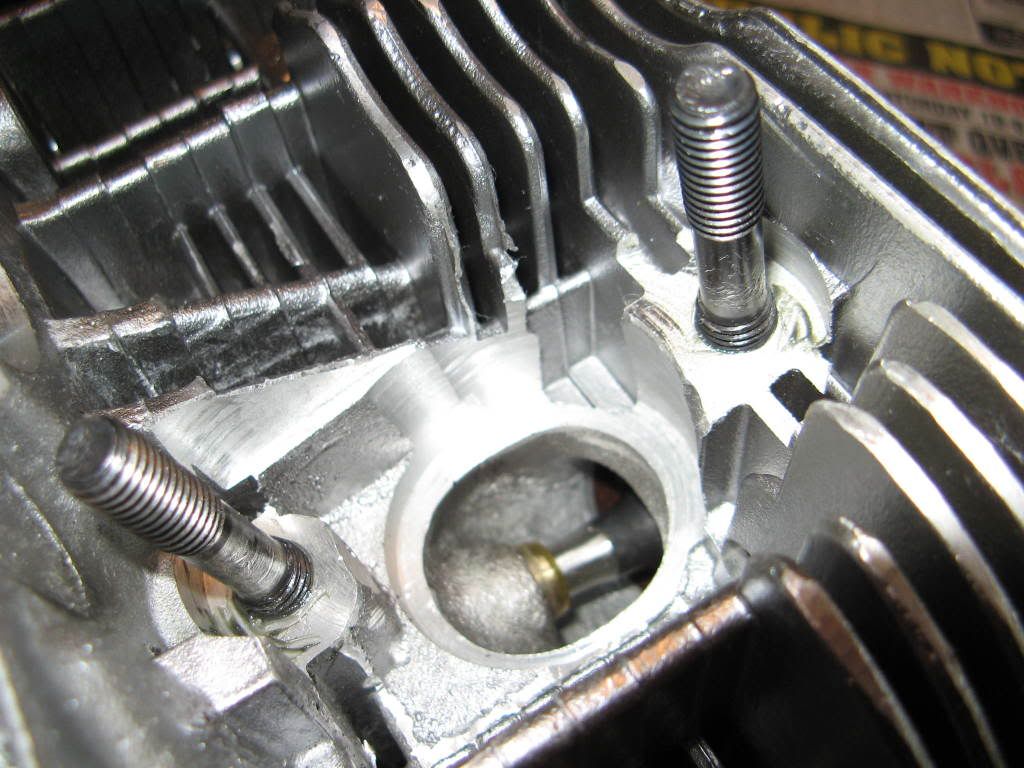

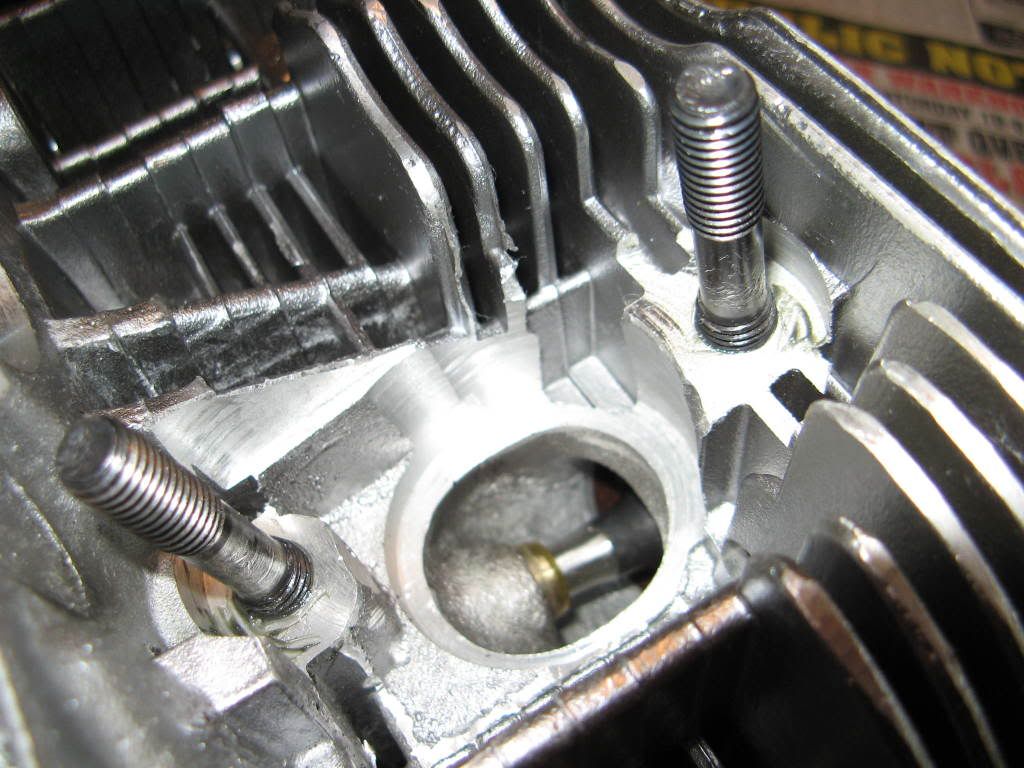

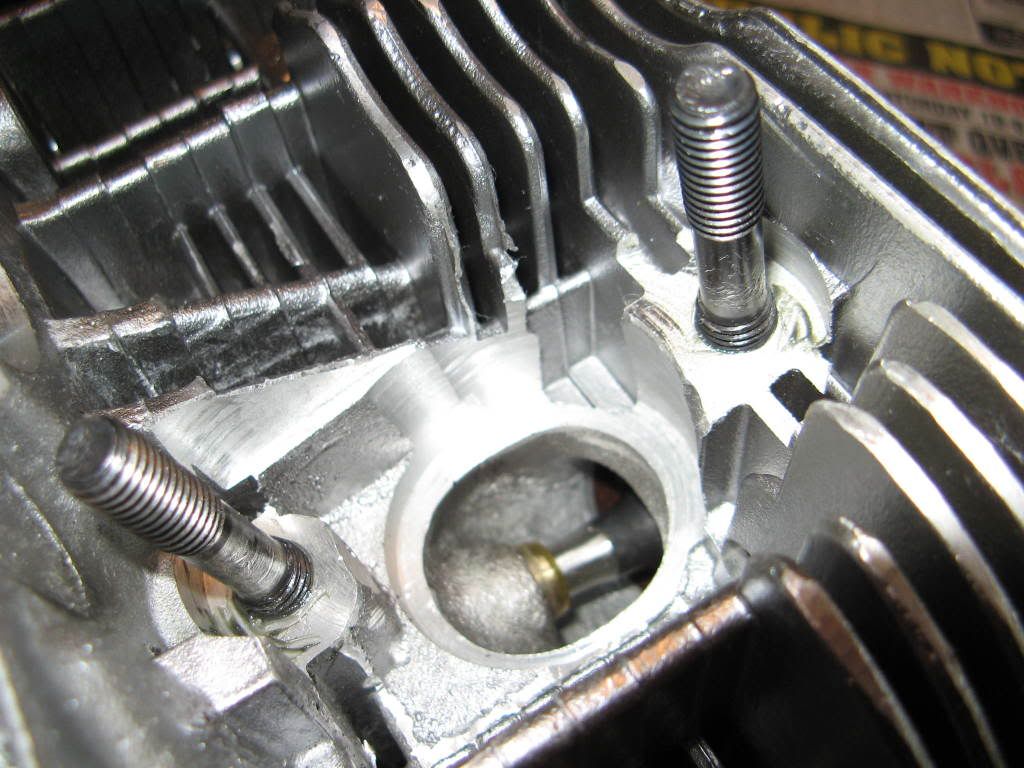

Do these look seated correctly? They seem to be bottomed out, I can't turn them any further, but there is still a decent amount of thread exposed.

As long as you're looking, should I goop this with some red rtv under the stud? Looks like a leak waiting to happen. I noticed on my old heads, this spot was oily and grimy.

-John

Keep it acoustic.

-

vdubyah73

- IAC Addict!

-

Status:

Offline

Post

by vdubyah73 » Sat Mar 14, 2009 4:01 pm

They look like step studs. Try to find a bottoming tap for blind holes, best bet. Or you could open the holes in the manifold enough that they will sit right over the step. How far does the stud go in? I'd be leery of suggestion 2 if they aren't in very far. Bad joke comes to mind. A filthy mind I guess.

Don't know about the machining hole.

1/20/2013 end of an error

never owned a gun. have fired a few.

-

vdubyah73

- IAC Addict!

-

Status:

Offline

Post

by vdubyah73 » Sat Mar 14, 2009 4:14 pm

is the step stud a 9mm or 10mm? Sears has a 10mm, they call it a plug tap. Napa has a 9mm

1/20/2013 end of an error

never owned a gun. have fired a few.

-

spiffy

- IAC Addict!

- Location: Walla Walla, WA

-

Status:

Offline

Post

by spiffy » Sat Mar 14, 2009 4:39 pm

The studs should go down all the way. That being said the important part is that the manifold seats right and can be tightened down. As long as you can achieve that then the threads showing would not be a problem.

I would be leary with making the holes bigger as you and I do not have the tools in our garage to make sure the holes are straight and that we would not change the way the manifold lines up with the port.

Maybe file some material off the end of the studs?

78 Riviera "Spiffy"

67 Riviera "Bill"

-

LiveonJG

- IAC Jester!

- Location: Standing on the side of the road, rain falling on my shoes.

-

Status:

Offline

Post

by LiveonJG » Sat Mar 14, 2009 4:50 pm

Thanks for the replies. I looked at my old heads and while some studs were seated firmly, a few others looked a lot like these. I don't think this will effect the heat exchangers as there seems to be more than enough room between the ears and the head. As for how deep they are in, I would estimate about an inch or so. They went in fairly easily, leaving little doubt when they hit bottom. I used vise grips to finish them off.

How about the red rtv question?

-John

Keep it acoustic.

-

vdubyah73

- IAC Addict!

-

Status:

Offline

Post

by vdubyah73 » Sat Mar 14, 2009 4:57 pm

I meant enlarging the holes in the manifold ears so they will not get stuck trying to go over the exposed threads of the step studs. Later manifolds have deeper ears don't remember what year heat exchangers are on his bus.

1/20/2013 end of an error

never owned a gun. have fired a few.

-

spiffy

- IAC Addict!

- Location: Walla Walla, WA

-

Status:

Offline

Post

by spiffy » Sat Mar 14, 2009 5:01 pm

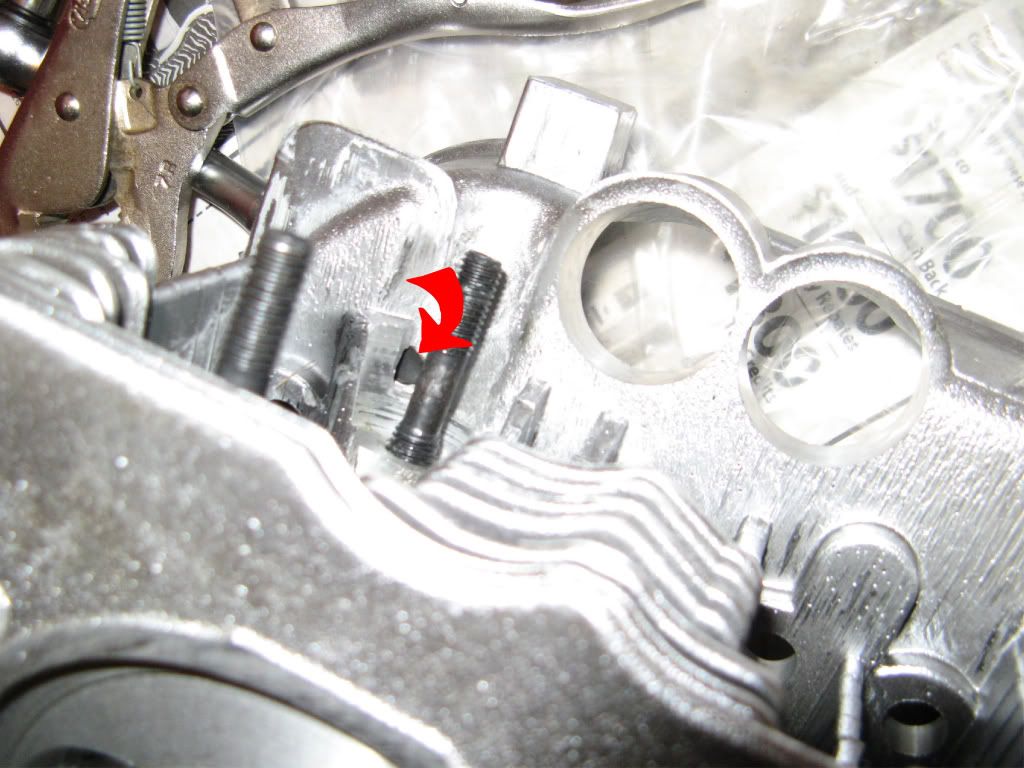

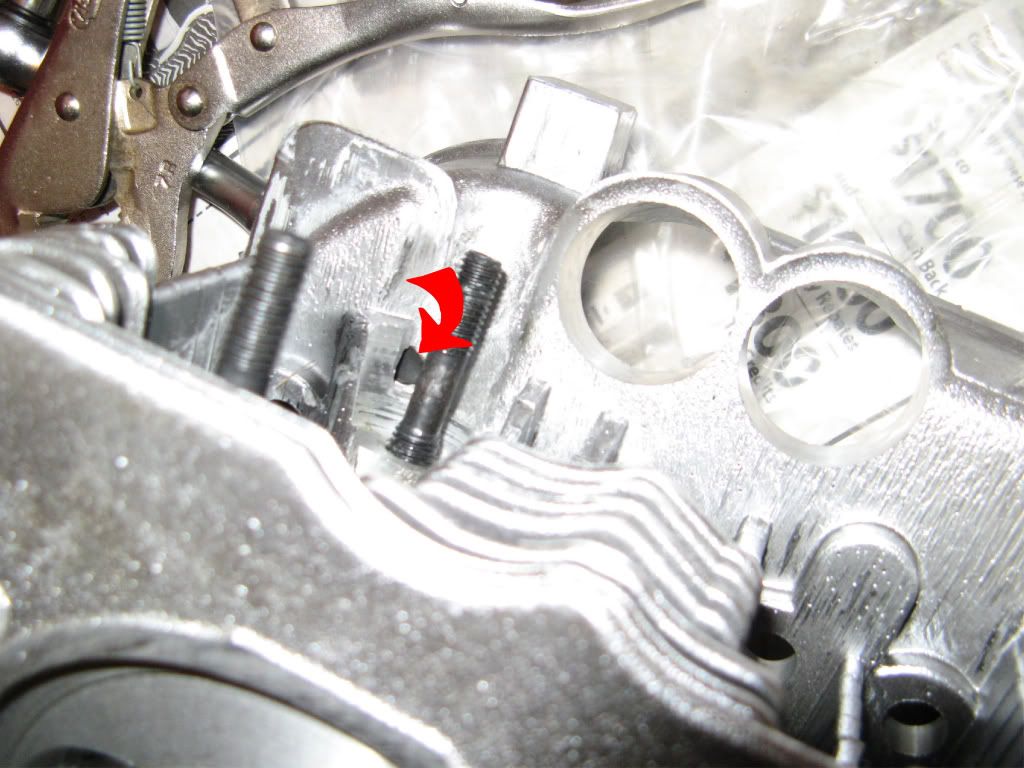

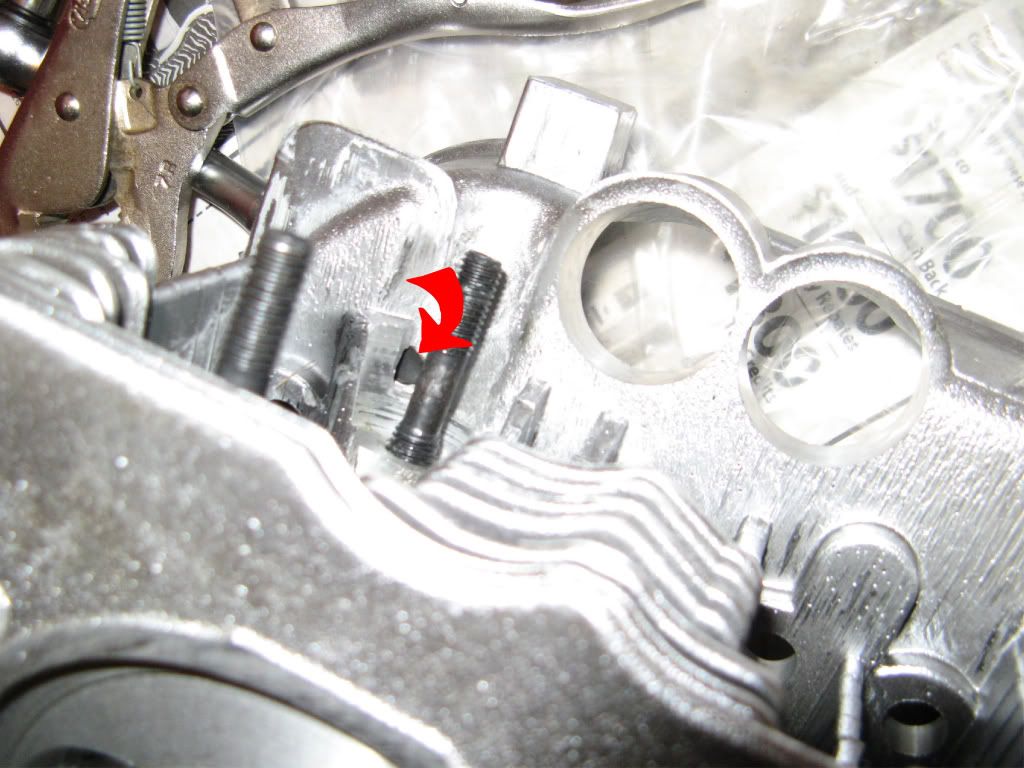

Is that a hole in the second pic? if so, does it go anywhere?

78 Riviera "Spiffy"

67 Riviera "Bill"

-

LiveonJG

- IAC Jester!

- Location: Standing on the side of the road, rain falling on my shoes.

-

Status:

Offline

Post

by LiveonJG » Sat Mar 14, 2009 5:44 pm

Bill, they are 72-74 HEs. After looking at them and my old head, I probably overreacted. I think they'll be fine.

Mike, that is a hole, it's filled by one of the rocker assembly studs. I'm thinking about some locktite on those studs, but before I do that, I was wondering if I shouldn't seal that hole.

-John

Keep it acoustic.

-

spiffy

- IAC Addict!

- Location: Walla Walla, WA

-

Status:

Offline

Post

by spiffy » Sat Mar 14, 2009 6:42 pm

I guess some goop couldn't hurt but what could leak out of there?

78 Riviera "Spiffy"

67 Riviera "Bill"

-

Amskeptic

- IAC "Help Desk"

-

Status:

Offline

Post

by Amskeptic » Sat Mar 14, 2009 6:44 pm

LiveonJG wrote:Bill, they are 72-74 HEs. After looking at them and my old head, I probably overreacted. I think they'll be fine.

Mike, that is a hole, it's filled by one of the rocker assembly studs. I'm thinking about some locktite on those studs, but before I do that, I was wondering if I shouldn't seal that hole.

-John

Those were not step studs. The number of threads sticking out is not worrisome. Do not deepen the hole at this time. You now have a reserve for future drilling, tapping. Do not force these studs in. They do not back out. You run the risk of tearing the threads when the engine warms up if you jam them in too tight now. The only time these things loosen is when threads tear out of the head, that seems to motivate people to overtighten (bad) or send the studs in too tight (bad) when the correct thing to do is to put them in lightly and torque the nuts lightly to 15 ft/lbs AND RE-CHECK in 100 miles, and again at your first valve adjustment at 3,000 miles. Kapiche?

Colin.

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

-

LiveonJG

- IAC Jester!

- Location: Standing on the side of the road, rain falling on my shoes.

-

Status:

Offline

Post

by LiveonJG » Sat Mar 14, 2009 7:10 pm

Thanks Colin.

-John

Keep it acoustic.